You have successfully logged out.

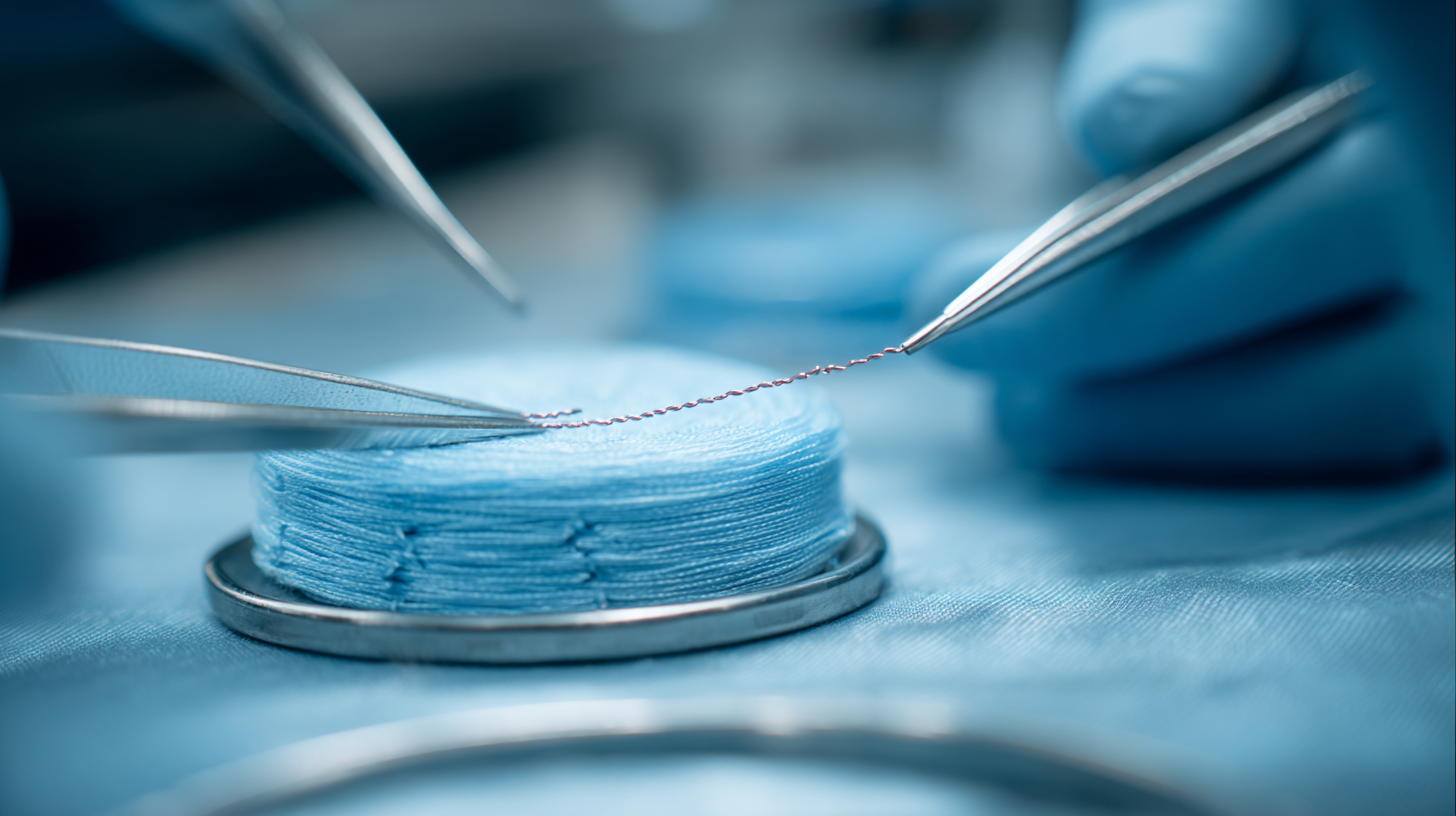

Quality Suture Supplies from China Your Trustworthy Global Manufacturing Partner

In the ever-evolving medical landscape, the demand for high-quality suture supplies is paramount, as surgical procedures become increasingly sophisticated. According to a recent report by Research and Markets, the global sutures market is projected to reach USD 5.7 billion by 2025, driven by the rising number of surgical interventions and advancements in healthcare technologies.

China has emerged as a key player in this sector, known for its cost-effective manufacturing capabilities and a wide range of suture products that meet international quality standards. As healthcare providers continue to seek reliable partners for their suture supply needs, aligning with a trustworthy global manufacturing partner can ensure not only compliance with stringent regulations but also enhance the overall effectiveness of surgical practices worldwide. Understanding the landscape of suture supplies from China is crucial for healthcare professionals aiming to optimize their surgical outcomes.

The Rising Demand for Quality Suture Supplies in the Global Market

The global market for medical supplies has witnessed a significant surge in demand, particularly for quality suture supplies. As healthcare systems strive to enhance patient outcomes, the importance of reliable and effective sutures cannot be overstated. Surgeons and healthcare providers are increasingly seeking high-quality sutures that not only meet rigorous medical standards but also ensure safety and efficacy during surgical procedures.

China has emerged as a key player in meeting this rising demand. With a robust manufacturing infrastructure and an emphasis on quality control, Chinese manufacturers are able to deliver a wide array of suture supplies. These products not only cater to the needs of local markets but also penetrate global arenas, providing healthcare professionals with innovative solutions. As the demand for specialized and durable suture materials continues to grow, partnering with trusted suppliers from China can greatly enhance the availability of reliable medical products, ultimately benefiting patient care worldwide.

Advantages of Sourcing Suture Supplies from China

Sourcing suture supplies from China offers numerous advantages for companies seeking reliable and cost-effective solutions. China's extensive manufacturing infrastructure and expertise in producing high-quality medical supplies provide businesses with the assurance of consistency and reliability. The country's established supply chains and competitive pricing enable manufacturers to lower production costs while maintaining quality standards, making it an attractive option for global sourcing.

As we delve into the advantages, it’s important to consider some tips when choosing a manufacturer. Firstly, always assess the manufacturer's certifications and quality control measures to ensure they adhere to international safety standards. Secondly, establish clear communication channels to avoid misunderstandings and ensure that your specifications are met. Engaging in regular updates and site visits, if possible, can help maintain transparency throughout the production process.

Moreover, the concept of "China Plus One" is gaining traction, emphasizing the importance of diversifying your supplier base. This strategy not only mitigates risks associated with relying on a single source but also enhances flexibility in the supply chain. Incorporating domestic partners while sourcing from China can create a robust network that delivers reliability and efficiency in delivering suture supplies globally.

Ensuring Quality Control in Suture Manufacturing Processes

In the competitive landscape of medical supplies, ensuring quality control in suture manufacturing processes is paramount. Reports suggest that the global sutures market is expected to reach $4 billion by 2025, with a compound annual growth rate (CAGR) of 5.4%. The demand for sutures is steadily rising due to the increasing number of surgical procedures and advancements in wound closure techniques. To maintain this growth, manufacturers must adopt rigorous quality assurance protocols.

Quality control in suture manufacturing involves multiple stages, from raw material selection to final product testing. According to the International Organization for Standardization (ISO), adherence to ISO 13485—a standard for medical device quality management systems—is crucial for manufacturers. This standard promotes consistent quality in design, development, production, installation, and delivery of medical devices, including sutures. Additionally, advanced technologies such as automated inspection systems and biocompatibility testing are becoming essential to ensure that sutures meet stringent safety and efficacy standards before they reach healthcare providers and patients. By prioritizing quality control, manufacturers can enhance their reputation and expand their market reach, making them trustworthy global partners in the medical supply chain.

Quality Suture Supplies from China - Ensuring Quality Control in Suture Manufacturing Processes

| Suture Type | Material | Diameter (mm) | Length (cm) | Pack Size | Sterile | Quality Certification |

|---|---|---|---|---|---|---|

| Absorbable | Polyglycolic Acid | 0.5 | 75 | 12 | Yes | ISO 13485 |

| Non-Absorbable | Polypropylene | 0.4 | 50 | 24 | Yes | CE Marked |

| Monofilament | Nylon | 0.3 | 100 | 6 | No | ISO 9001 |

| Braided | Silk | 0.5 | 75 | 12 | Yes | FDA Approved |

Building Trust: The Role of Partnerships in Global Trade

In the realm of global trade, partnerships are pivotal in navigating the complexities of international supply chains. By forming strategic alliances, manufacturers and suppliers can leverage each other's strengths, foster innovation, and enhance product quality. This collaborative spirit not only bolsters individual businesses but also contributes to the reliability and trustworthiness that customers seek in their sourcing decisions. A partnership rooted in transparency and mutual respect can significantly enhance the customer experience, ensuring that the products meet both market demands and regulatory standards.

Quality suture supplies from China exemplify this dynamic. Manufacturers that prioritize partnerships with both local suppliers and international distributors create a robust network that enhances efficiency and reliability. This interconnectedness allows for real-time feedback and agility in meeting varying client needs, ultimately resulting in high-quality products delivered promptly. As these partnerships grow, so does the confidence of global customers in their suppliers, solidifying long-term relationships that benefit all parties involved. Trust is not merely a transaction—it is the cornerstone of successful global trade, enabling manufacturers and suppliers to thrive in an increasingly competitive landscape.

Quality Suture Supplies Market Overview

This chart displays the global market share of different suture supply materials used in medical applications, highlighting the importance of quality partnerships in global trade.

Innovations in Suture Technology from Chinese Manufacturers

Innovations in suture technology from Chinese manufacturers have transformed the landscape of surgical supplies, driving efficiency and safety in medical procedures. Recent industry reports indicate that the global surgical sutures market is expected to reach approximately $6 billion by 2027, with a compound annual growth rate (CAGR) of 5.2% from 2020 to 2027. This growth is largely attributed to advancements in materials and designs, with Chinese manufacturers leading the way in developing bioabsorbable sutures and enhanced needle technology, which aim to reduce healing times and minimize scarring.

Tips for healthcare professionals considering new suture supplies include assessing the specific needs of different surgical procedures, as various types of sutures offer unique benefits. For instance, the use of advanced synthetic materials can significantly enhance tissue integration and reduce the risk of infection. Furthermore, staying informed about the latest innovations can ensure that practitioners utilize the most effective tools available, leading to improved patient outcomes.

Chinese manufacturers are also investing heavily in research and development to create smarter suturing solutions. Innovations such as sutures with antimicrobial properties and those that provide real-time feedback during surgeries are becoming increasingly common. By embracing these advancements, medical facilities worldwide can not only enhance their surgical capabilities but also contribute to the overall improvement of healthcare practices globally.