Navigating Industry Standards: The Gold Standard for Best Suture Needles in Surgical Precision and Safety

In the rapidly evolving field of surgical procedures, the importance of selecting the right tools cannot be overstated, especially when it comes to suture needles. According to a report published by the Global Surgical Sutures Market, the demand for high-quality suture needles is expected to grow significantly, driven by advancements in surgical techniques and an increasing emphasis on patient safety. The precision offered by quality suture needles not only enhances surgical outcomes but also minimizes the risk of complications, underscoring their role as a cornerstone of effective surgical practice. As healthcare professionals strive to meet industry standards, comparing various types of suture needles becomes imperative in achieving the gold standard for surgical precision and safety. This blog will navigate the current landscape of suture needle options, providing insights into which types are best suited for specific surgical applications while adhering to the highest industry benchmarks.

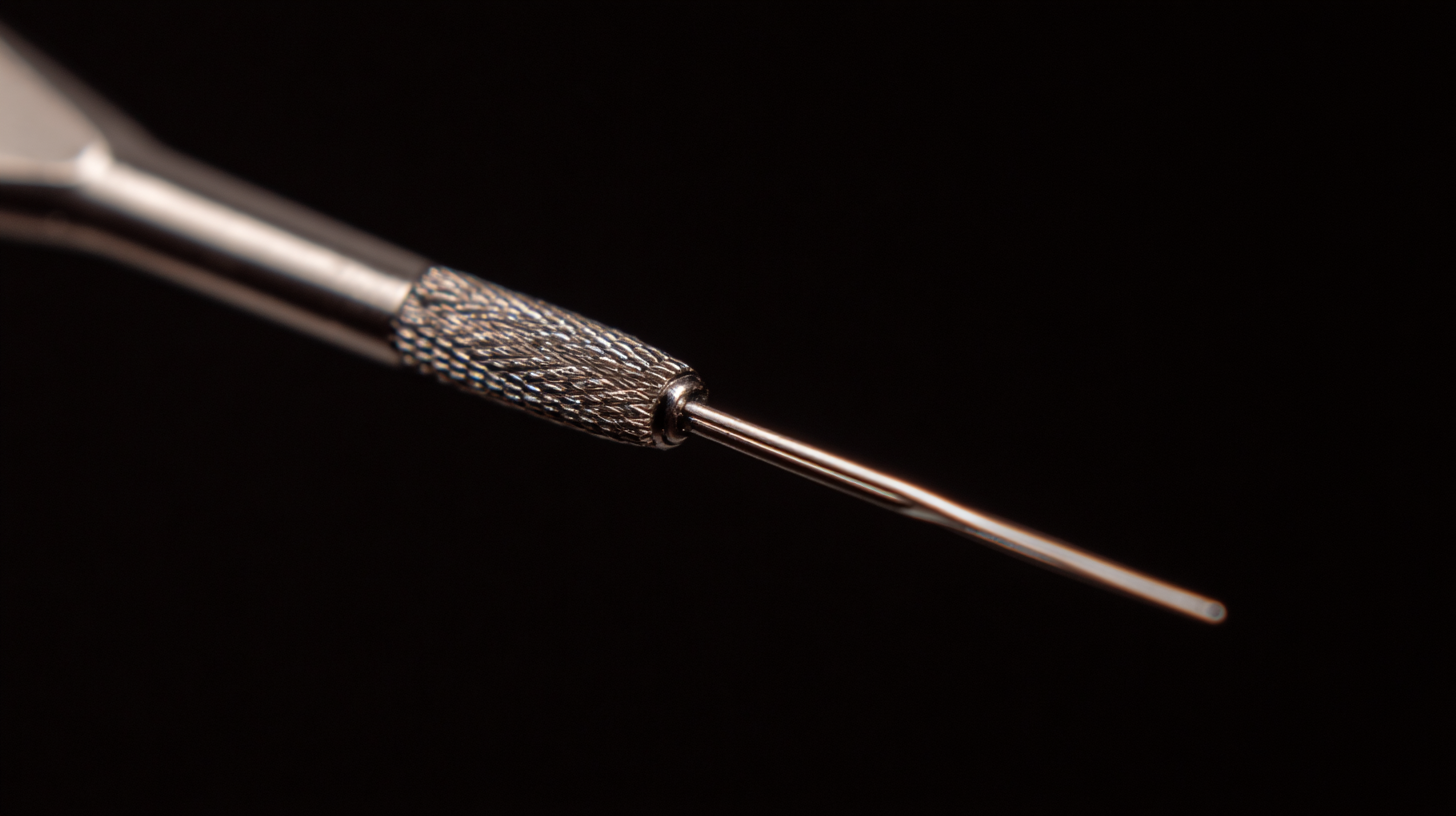

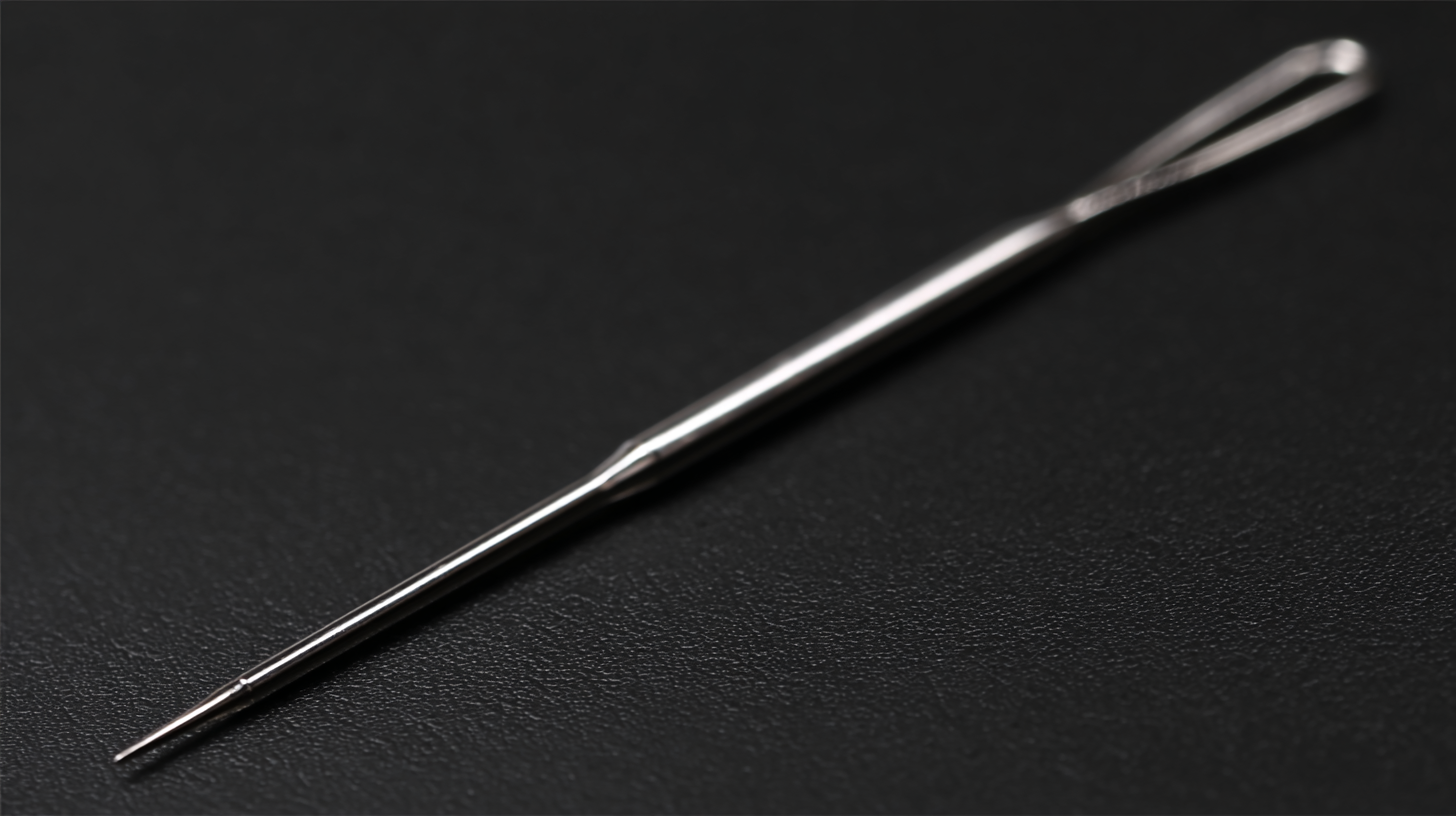

Identifying Key Features of High-Quality Suture Needles for Surgical Excellence

When it comes to surgical procedures, the quality of suture needles plays a crucial role in achieving precision and ensuring patient safety. High-quality suture needles are designed with specific features that enhance their performance in various surgical environments. One of the primary attributes to look for is the sharpness of the needle. A finely honed cutting edge allows for smooth penetration through tissues, reducing trauma and enhancing healing times. Furthermore, needles with a polished surface minimize friction, which can be especially beneficial during intricate procedures where control is paramount.

In addition to sharpness, the curvature and size of suture needles should also be considered. Needles come in various shapes and diameters, tailored for different types of surgeries and tissues. For instance, curved needles are often preferred for deep suturing in cavities, while straight needles might be more suitable for surface-level stitching. Additionally, high-quality needles are often made from durable materials such as stainless steel, which ensures they maintain their integrity and sharpness throughout the procedure. By focusing on these key features, surgeons can select the best suture needles that contribute to surgical excellence and ultimately improve patient outcomes.

Evaluating Supplier Reputation and Track Record in the Medical Industry

When it comes to surgical precision and safety, the selection of suture needles is paramount. Understanding the reputation and track record of suppliers in the medical industry is crucial for healthcare professionals aiming to provide the best care possible. A reputable supplier is not just about high-quality products; it signifies a commitment to rigorous safety standards, innovation, and consistent performance in diverse surgical environments.

Evaluating a supplier’s history involves examining their adherence to industry standards, certifications, and overall reliability. Suppliers who have established a strong presence in the market often showcase testimonials and case studies that highlight their products' efficacy and reliability. Additionally, it’s important to analyze the feedback from surgeons and medical staff who have experience with the products. This firsthand information can provide valuable insights into the usability and performance of different suture needles, helping to guide purchasing decisions effectively. Choosing a supplier with a solid track record not only enhances surgical outcomes but also fosters trust in the materials used within the operating room.

Understanding Regulatory Compliance Standards for Surgical Equipment Suppliers

In the world of surgical equipment, regulatory compliance is paramount for ensuring safety and effectiveness. Suppliers of surgical tools, particularly suture needles, must adhere to a series of stringent guidelines set by organizations such as the FDA and ISO. These standards not only govern the materials and manufacturing processes involved but also outline the necessary testing protocols to validate the performance and reliability of these critical instruments. Understanding these compliance requirements is essential for suppliers looking to maintain market trust and meet the medical community's high expectations.

In the world of surgical equipment, regulatory compliance is paramount for ensuring safety and effectiveness. Suppliers of surgical tools, particularly suture needles, must adhere to a series of stringent guidelines set by organizations such as the FDA and ISO. These standards not only govern the materials and manufacturing processes involved but also outline the necessary testing protocols to validate the performance and reliability of these critical instruments. Understanding these compliance requirements is essential for suppliers looking to maintain market trust and meet the medical community's high expectations.

Moreover, navigating these complex regulations can pose challenges for manufacturers. It requires a comprehensive approach to quality assurance that integrates both design controls and risk management practices. Suppliers must stay abreast of varying standards, as any lapses in compliance can lead to severe repercussions, including product recalls and legal liabilities. By prioritizing regulatory adherence, surgical equipment suppliers can ensure their products meet the "gold standard" of safety and precision, ultimately contributing to improved patient outcomes and enhancing their reputation within the healthcare industry.

Tips for Assessing Material Quality and Performance of Suture Needles

When selecting suture needles, assessing material quality and performance is crucial for ensuring surgical precision and patient safety. According to a report by the Association for the Advancement of Medical Instrumentation (AAMI), the mechanical properties of needle materials, such as tensile strength and ductility, greatly influence their performance during procedures. Stainless steel remains the industry standard due to its balance of strength and resistance to corrosion, which can otherwise lead to needle breakage or tissue trauma during suturing.

Moreover, the needle's coating significantly impacts its glide and penetration characteristics. Research published in the Journal of Surgical Research indicates that needles with a silicone coating exhibit a 30% improvement in smoothness compared to non-coated counterparts, reducing both force required for penetration and trauma to the surrounding tissues. Surgeons must evaluate these factors carefully, as a high-quality suture needle not only enhances the efficiency of the procedure but also minimizes the risk of complications such as infections or delayed healing. Effective assessment of suture needles should involve rigorous testing against established industry standards, ensuring the best outcomes in surgical practice.

Navigating Industry Standards: Suture Needles Material Quality and Performance

Building Strong Relationships with Suppliers for Better Surgical Outcomes

Building strong relationships with suppliers is essential for achieving better surgical outcomes. A reliable supplier not only provides high-quality suture needles but also offers valuable insights into industry standards and innovations. Establishing trust and open communication with suppliers can lead to improved product knowledge and customizable solutions that cater to the specific needs of surgical teams. Regular meetings and feedback sessions can foster a collaborative environment where both parties can share experiences and discuss challenges.

**Tip:** Choose suppliers that prioritize quality assurance and have a track record of adhering to industry standards. This commitment ensures that the products received are reliable and safe for use in surgical procedures.

Additionally, maintaining a strong network with suppliers enables surgical practitioners to stay ahead of advancements in technology and techniques. Suppliers can provide training or resources that can enhance surgical precision and safety. By engaging in joint ventures or initiatives with suppliers, surgeons and healthcare facilities can explore new materials and products that may improve surgical outcomes.

**Tip:** Invest in ongoing education and training programs offered by suppliers to keep your surgical team updated on the latest techniques and best practices. This not only enhances skills but also strengthens the partnership between the surgical team and the supplier.